How to Improve Life of Forging Die Steel ?

The below measures to improve the die steel of span life and reducing the cost in production.

To strengthen industry management and establish the strictly implement rules and regulations so it could to improve the span life of forging dies and reduce the cost in the same time .

Reasonable design of forgings dies may reduce manufacturing costs and increase die life.

1、 Therefore, it strictly accordance with the design specifications of forgings and dies, the dimensional accuracy of the die, parting line, inner and outer fillet radius, rib, web, burr groove and other key factors are carefully designed.

2、 It is necessary to choose the parameters rationally and strictly implement the system of design, check, review, countersign and approval to improve the economy of the mold.

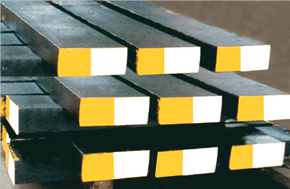

3、 Formulate size and quality standards of mold materials and modules, and implement fixed-point production (standardize module forging, heat treatment process and rough shape machining) and acceptance system.

4、 This increases the production of mold materials and modules, the implementation of professional, batch production, in order to improve the production process and equipment, improve quality and reduce production costs.

3、It also use advanced extrusion and superplastic forming die chamber, die surfacing manufacturing and repair technology and die chamber surface treatment technology, it not only can improve the life of the die, but it also can reduce the cost of the die, significantly improve the economy of the die.

A.Improve the span life of the die steel basically without increasing the cost .

The measures to improve the span life of the forging die without increasing the cost in the same time which are mainly to establish and strictly implement the operation, maintenance and storage norms.

To avoid the early brittle fracture of the mold caused by improper installation of the mold, too low preheating temperature or overheating, uneven preheating temperature, cold strike and other non-standard operations.

When the mold and forgings bonding and abrasion, should stop using, timely repair, in order to prevent the surface of the mold chamber to further deteriorate to the extent that can not be repaired.

B.Protect and lubricate the die chamber and blank in strict accordance with the technical requirements.

Mold that are not used or newly processed for the time being must be oil sealed and stored in a dry, ventilated and non-corrosive medium mold library.

C.A measure that greatly increases the span life of die steel with only slightly increases the cost for production

According to the characteristics of the specific forging process, the proper selection of high quality die materials and advanced heat treatment and surface strengthening technology of the die chamber can greatly increase the die life with only a little increase in the cost of the process.

·Select 3Cr3Mo3VNB, SRM-1, 3Cr2MoVNI (B2), 3Cr2MoWVN (B3), 35Cr3Mo3W2V (HM1), 25Cr3Mo3VNB (HM3), 4Cr3Mo3W4VTiNB (GR), and 5Cr4W5Mo2V (RM2).High-quality die steels such as 50Cr4Mo3SiMnVal (012Al), 6Cr4Mo3Si2WV(CG-20) replace conventional die materials, as well as high quality die materials such as 7CrSiMnMoV(CH), 65Cr4W3Mo2VNB (65NB), SLM-11,6W8Cr4VTi(LML), hard alloy and steel-cemented cemented carbide .To greatly improve the span life of the die and with only a little increase in the cost of the process .

Because the mold material cost only accounts for about 25% of the mold cost. Assuming that the high quality mold material is 1 times higher than the price of ordinary mold material and the service life is also 1 times higher, roughly calculated, due to the increase in the cost of mold material, the mold cost increases by 25%, and the mold life is increased by 1 times.

To adopt advanced shot peening, extrusion, rolling and other chamber surface deformation strengthening technology and ion implantation technology, soft nitriding, carburizing, nitriding, boronizing and multiple expansion infiltration technology such as permeability, physical vapor deposition technology such as thin film technology and thermal spraying coatings to strengthen mold surface of the chamber into the line and its cost little, but can be multiplied several times or to increase the die life.

The use of advanced lubricant and its lubrication technology can also greatly improve the life of the die and only a little increase in cost.For example, glass protection lubrication technology is used in the production of high temperature alloys, titanium alloys and stainless steel forgings

D.Mold life and die cost synchronous improvement measures

In the adoption of technical and management measures, there may be a synchronous increase in die life and die cost with little difference.,

for example, choose high quality high price of the mold material and advanced processing technology, improve the die life, but it also increase the mold cost, because it from a purely die life was compared with the "mold directly cost", it's hard to tell in this case, the up and down still suggest to choose the high quality high price of the mold manufacturing mold materials and advanced processing technology.

Because the life of the die is long, the indirect costs such as replacement, adjustment and maintenance are reduced, which is cost-effective from the comprehensive economic indicators. In addition, the development space of new materials and new technologies is large, and the potential can be further tapped in the process of accumulating experience. Therefore, considering the long-term development and technological progress of enterprises, new technologies are recommended.

In a word, the life of the die and the die cost are closely related. Both of them restrict and promote each other. It is not necessary to overemphasize any one of the factors.

Therefore, in order to obtain the best economic benefits, it is necessary to comprehensively analyze the relationship between the cost of the die and the life of the die, compare the technology and economy of several schemes, and select the best scheme.

Solar Special Steel International Limited

Email: ss@solarsteel.cn

Whatsapp /Wechat /Skype :+86 18688633122