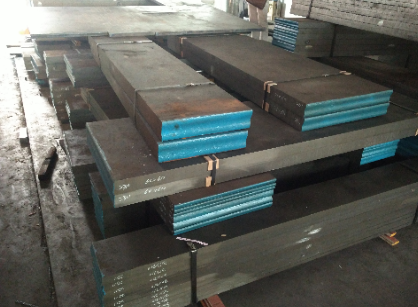

Cr12MoV Steel Introduction

From: Author:ss@solarsteel.cn Publish time:2021-10-11 09:45 Clicks:18

Cr12MoV steel belongs to high carbon and high chromium steel with high carbon content and high chromium content, forming a large amount of carbides and martensite with high alloying degree. Make steel have high hardness and high wear resistance.

The molybdenum in Cr12MoV steel increases the harden-ability of the steel and refines the grains, while vanadium can refine the grains and increase the toughness. It can also form high hardness VC to further increase the wear resistance of steel. Chromium also makes steel have high harden-ability and tempering stability.

Due to the large amount of Cr, a large number of eutectic carbides (mainly the high-hardness ferrochrome composite carbide (Fe, Cr) 7C3) precipitated during the crystallization of molten steel are extremely stable and cannot be refined by conventional heat treatment. Even after calendering, it is in the larger specification steel. Obvious band-shaped or network-shaped carbides are still retained, and the distribution of carbides is uneven, while the band-shaped or network-shaped carbide zone is a brittle zone with poor plasticity and toughness, and cannot withstand large impact forces. Cracks are easy to The initiation and expansion here often become the main cause of cracks.

There are often defects such as cavities and dislocations around larger carbides. Under the action of alternating load, these defects can further accumulate and expand to induce fatigue cracks. Carbide segregation is serious. In areas where carbon and alloying elements are enriched, the melting point of steel decreases, which easily leads to overheating of the mold during heat treatment, which reduces the solubility of carbon and alloying elements in austenite, reduces the hardness after quenching, and leads to carbon alloys Large tissue stress is generated between the element-rich area and the poor area, thereby increasing the deformation of the mold after heat treatment.

In order to crush and refine the eutectic carbides, the coarse dendritic eutectic carbides are broken up, the uniformity of the carbide distribution is improved, and the particle size of the carbides is refined. Generally, Crl2MoV requires forging and pre-heat treatment to reduce the uneven distribution of carbides and provide excellent original structure for subsequent quenching and tempering. In addition, the modification treatment by adding a trace amount of zinc element will accelerate the eutectic carbide

The kinetic process of heat treatment granulation promotes the granulation of eutectic carbides. At present, there are many factors that cause damage to the high-carbon and high-chromium steel molds of Crl2MoV, but the main ones are caused by the forging process and the heat treatment process. Wire cutting processing can sometimes cause mold cracks. The unevenness of carbides and the distribution of residual stress are the decisive factors affecting the service life of the mold.

Cr12MoV steel has poor thermal conductivity and narrow forging temperature, so the heating speed should not be too high. Heat evenly... Generally, forging is best to be carried out in the single-phase zone. Higher forging temperature is prone to plastic deformation. However, Crl2MoV steel has a low eutectic temperature (about 150°C), and overheating and overburning will occur if you are not careful. Too low opening forging temperature narrows the range of opening and stopping forging temperature, and correspondingly increases the number of deformation fires. Too low final forging temperature will produce work hardening and cause internal and external cracks.

If the final forging temperature is selected above the Aam line, secondary network cementite will precipitate along the grain boundary during the cooling process after forging, which will greatly reduce the mechanical properties of the forging. Forging in the temperature range between the Aam and A1 lines, due to the mechanical destruction of plastic deformation, the precipitated secondary network can be made

The cementite is diffuse. The final forging temperature of Crl2MoV should be controlled below Aam line and 50~100℃ above Al line.

Solar Special Steel International Limited

Contact Person :Wendy

Telephone:+86 18688633122 whatsapp&wechat

Skype: .cid.8920082fecfa0b5c

Email:ss@solarsteel.cn