Cr12MoV Steel ‘s Vacuum Heat Treatment for Making Ceramic Molds

From: Author:ss@solarsteel.cn Publish time:2021-10-16 19:18 Clicks:17

Cr12MoV steel is widely used in Guangdong, Fujian Province and other areas where it is professional to manufacture ceramic molds.

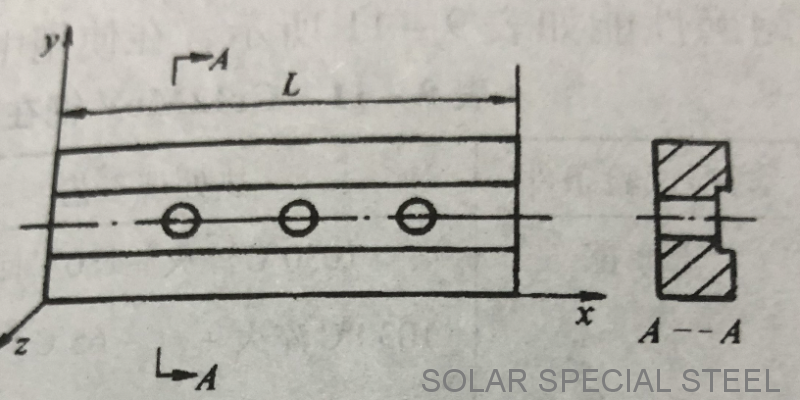

It can be seen from Figure 1 that the shape of the ceramic mold is simple, but there is a right-angle groove on its center line, and several assembly holes are distributed in it. During heat treatment, due to the effect of phase transition stress and thermal stress, especially when the mold length L≥400-600mm, it is easy to be distorted along the Y and Z axes. The required distortion is less than 0.25mm.

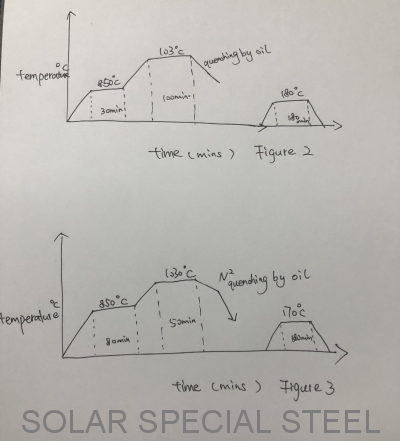

In the process of Figure 2, the distortion is out of tolerance, and the method of thermal straightening is needed to meet the requirement of distortion. After the improvement of the treatment process, when the ceramic mold is processed in the ZC2-100 two-chamber oil-quenched gas-cooled vacuum furnace (Figure 3), the distortion is less than 0.20mm in both directions along the Y axis and z axis, so there is basically no need to take thermal straightening. After x3h x2 times tempering at 170℃, the hardness is 62-63HRC.

In order to reduce the residual Austenite content and improve the hardness and wear resistance of the die, cold treatment was adopted after quenching. Keep in dry ice + craft alcohol at -65℃ for 1-1.5 hours, twice in total. After cold treatment, after 170℃ x3h x2 times tempering, the hardness is 64-65HRC, the wear resistance is shown in Figure 4-Cr12MoV Steel’s Wear resistance after cold treatment and good effect can be obtained in use.

Cr12MoV Steel’s Wear resistance after cold treatment

|

Wear test condition |

Wear test condition |

Wear rate x10 -4mm3/m |

|

Dry friction |

1030℃quenching +180℃ tempering 1030℃quenching +(-65℃)cooling process 1030℃quenching +180℃ tempering 1030℃quenching +(-65℃)cooling process

|

6.846 |

|

|

3.672 |

|

|

0.573 |

||

|

Rub under oil lubrication |

0.209 |

And now you know how to use Cr12MoV Steel to make the Ceramic Molds according to these Cr12MoV Steel’s data as the above mention .

Welcome you to inquiry with SOLAR SPECIAL STEEL INTERNATIONAL LIMITED coming soon .

Solar Special Steel International Limited

Contact Person :Wendy

Telephone:+86 18688633122 whatsapp&wechat

Skype: .cid.8920082fecfa0b5c

Email:ss@solarsteel.cn