Heat Treatment of High Carbon Chromium Bearing Steel

From: Author:ss@solarsteel.cn Publish time:2022-02-13 14:00 Clicks:72

The main purpose of spheroidizing annealing process of bearing steel in order to prepare the micro-structure for the final quenching treatment.

The size, shape and uniformity of carbide in spheroidizing annealing are mainly determined by the pearlite morphology, spheroidizing annealing process and cooling mode.

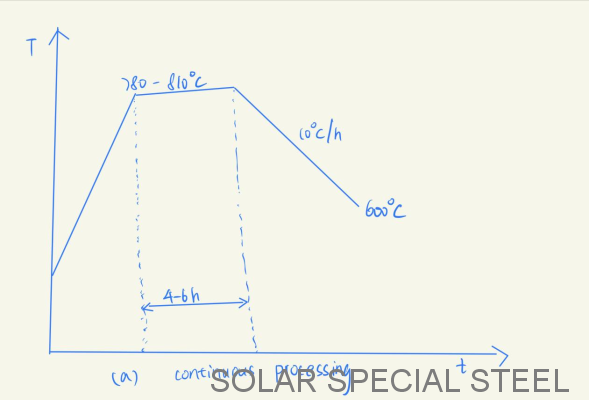

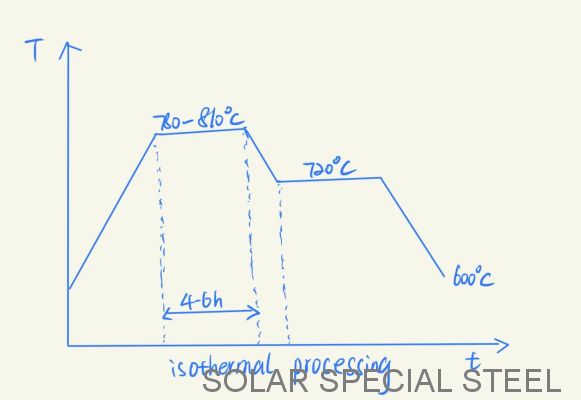

The heating temperature of spheroidizing annealing is generally 780-810℃, and there are two cooling methods: continuous cooling and isothermal transformation, as shown in the following 2 figures。

It is generally believed that continuous cooling is better than isothermal transformation and can eliminate the influence of the fluctuation of the stability of undercooled austenite on the annealing micro-structure.

The spheroidizing annealing structure of bearing steel has great influence on the fatigue strength, toughness and wear resistance of bearing parts.

That’s why the bearing steel ask for the spheroidizing annealing process for the production .

According to GB/T18254-2016 standard, the annealing material with a diameter of no more than 60mm for cold processing should have a qualified annealing structure of 2-4.

The ultimate goal of performance requirements for bearing steel is durability and stability of contact fatigue life. The general process route of bearing steel is as follows: forging (rolling) → spheroidizing annealing → mechanical processing → quenching and tempering → grinding. The process is characterized by simple process but high requirement.

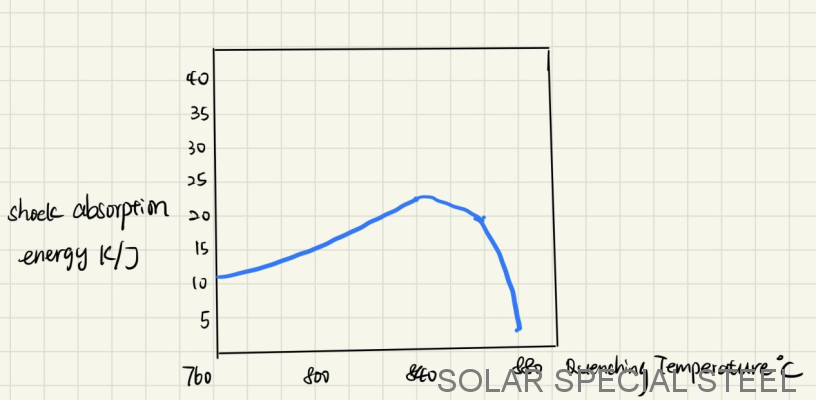

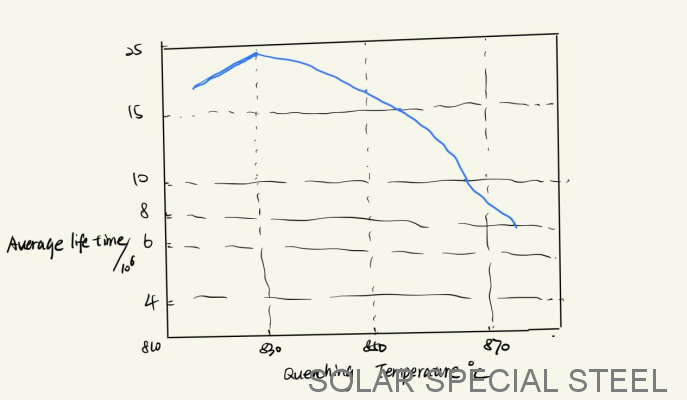

The selection of quenching and tempering process parameters has great influence on the service performance and fatigue life of bearings .The following figure shows the influence of quenching temperature on shock absorption energy and contact fatigue life of GCr15 steel.The quenching temperature of high carbon chromium bearing steel is 830-860℃. After oil quenching, fine and uniform grain size of grade 5-8 Austenite can be obtained. The content of C in the solid solution is generally 0.5-0.6%.Maximum hardness, bending strength and toughness can be obtained from such micro-structure properties.

Some studies indicated that the fatigue performance is best when C content in martensite matrix is about 0.45%;If C content in Martensitic matrix is fixed at 0.45%, the appropriate volume fraction of carbides is 4-6%.

Therefore, in some cases, it is advantageous to reduce the C content in steel.In the quenching process of bearing parts, oxidation and decarburization should be reduced as far as possible, and heating in protective atmosphere or vacuum is generally adopted.

Bearing steel should be tempered in time after quenching in order to improve the stability of the structure and size of the parts and improve the mechanical properties.Tempering is generally kept at 160℃ for 3 hours or longer. After tempering, the structure is tempered Martensite + dispersed carbide + a little residual Austenite.

The hardness after tempering is 62-66HRC.The basic reason for the size instability of bearing parts lies in the existence of internal stress and residual Austenite. The common measures to increase the structure instability and reduce stress are cold treatment and additional tempering.Especially for precision bearings, in order to ensure the stability of dimensional accuracy, it is necessary to eliminate residual Austenite.Generally, cold treatment is carried out immediately after quenching (-70 to -80℃).

In production, it is generally required that the time between quenching and cold treatment should not exceed 4 hours at room temperature, and low temperature tempering is carried out immediately after cold treatment.After grinding, bearings should be tempered to eliminate grinding stress. Generally, different holding time and tempering times should be selected according to the precision grade of bearings.

Generally lower than the original tempering temperature 20-30℃ temperature for additional tempering, such as 120-150℃ insulation 3-5 hours. Especially high precision requirements, in rough grinding, fine grinding and fine grinding after 2-3 times of tempering, time in 15-24 hours.

Solar Special Steel International Limited

Contact Person :Wendy

Telephone:+86 18688633122 whatsapp&wechat

Skype: .cid.8920082fecfa0b5c

Email:ss@solarsteel.cn