Detailed Introduction

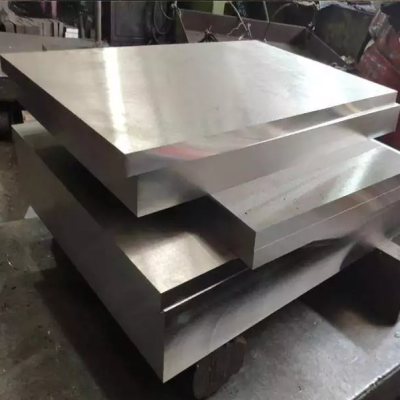

Model : 1.2355/50CrMoV13-15/ S7

Application : hot working tool steel

Content : Equivalent Steel with exact or nearest equivalents

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

1.2355 |

0.45-0.55 |

0.20-0.80 |

0.50-0.90 |

≤0.030 |

≤0.030 |

3.00-3.50 |

1.30-1.70 |

0.15-0.35 |

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

50CrMoV13-15 |

0.45-0.55 |

0.20-0.80 |

0.50-0.90 |

≤0.030 |

≤0.030 |

3.00-3.50 |

1.30-1.70 |

0.15-0.35 |

|

Grade |

C |

Mn |

P |

S |

Si |

Cr |

V |

Mo |

|

S7 |

0.45-0.55 |

0.20-0.90 |

≤0.030 |

≤0.030 |

0.20-1.00 |

3.00-3.50 |

≤0.35 |

1.30-1.80 |

Mechanical properties

|

ReH |

Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite d elasticite minimale |

|

Rm |

Tensile strength / Zugfestigkeit / Resistance a la traction |

|

A |

Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal |

|

J |

Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc |

HEAT TREATMENT AND HARDNESS FOR COLD WORK ALLOY TOOL STEEL 1.2355

|

Hardness after annealing ≤HBW : |

248

|

|

Quenching temperature ℃ ±10℃ : |

1010 |

|

Cooling medium: |

Oil

|

|

Tempering temperature ℃ ±10℃ : |

510

|

|

Hardness value after tempering /≥ HRC: |

56

|

MELTING PROCESS

This steel is generally smelt in electric arc furnace (EAF ) or IFF + VD, LF + Electroslag remelting (ESR).

For a purpose of higher quality, it should be smelt via technology of vacuum refining.

TYPICAL APPLICATIONS

1.Alloy tool steel is widely used to produce the cutting tool, cold/heat distortion mould and measuring implements,and further to manufacture the piston, valve, valve seat of fuel pump of diesel engine.

2.Cutlery for medical equipments

3.Cutting tools

4.Mechanical parts

5.Air hammer tools

6.Piercing tools

HEAT TREATTMENT PRACTICE

The preheating of measuring and cutting tool steel is spheroidizing annealing, final heat treatment is quenching + low temperature tempering and hardness after heat treatment can reach 60~65HRC.

When heat treat tool steel grades consideration should be given to hardening temperature, including ratio of heating, cooling and soaking times which will differ due to factors such as the shape and size of each chemical component.

Other considerations during heat treatment include the type of furnace, quenching medium and work piece transfer facilities.

Solar Special Steel International Limited

Contact Person :Wendy

Telephone:+86 18688633122 whatsapp&wechat

Skype: .cid.8920082fecfa0b5c

Email:ss@solarsteel.cn