Detailed Introduction

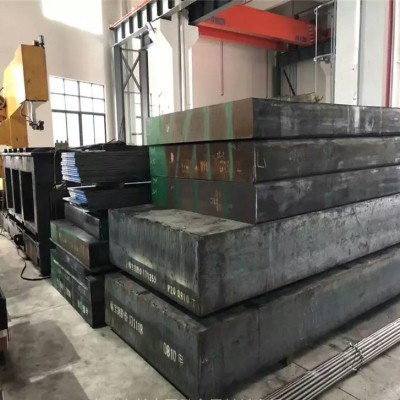

Model : 1.2365/32CrMoV12-28/3X3M3Φ/H10/4Cr3Mo3SiV

Application : hot working tool steel

Content :

Equivalent Steel

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

1.2365 |

0.28-0.35 |

0.10-0.40 |

0.15-0.45 |

≤0.030 |

≤0.030 |

2.70-3.20 |

2.50-3.00 |

0.40-0.70 |

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

32CrMoV12-28 |

0.28-0.35 |

0.10-0.40 |

0.15-0.45 |

≤0.030 |

≤0.030 |

2.70-3.20 |

2.50-3.00 |

0.40-0.70 |

|

Grade |

C |

Mn |

P |

S |

Si |

Cr |

V |

Mo |

|

H10 |

0.35-0.45 |

0.20-0.70 |

≤0.03 |

≤0.03 |

0.80-1.25 |

3.00-3.75 |

0.25-0.75 |

2.00-3.00 |

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

4Cr3Mo3SiV |

0.35-0.45 |

0.80-1.20 |

0.25-0.70 |

≤0.03 |

≤0.03 |

3.00-3.75 |

2.00-3.00 |

0.25-0.75 |

1.2365 Tool steel for hot working, used for production of press matrices, die inserts, molds for casting non-ferrous metals, tools and stamps for pressing and stamping. It is characterized by high harden-ability, excellent thermal conductivity, resistance to temperature differences during water cooling, and tempering resistance. It achieves hardness levels of 52 HRC.

Hardness :

1. Hardness in +A delivery condition: <229 HB

2. Hardness in +A+C delivery condition: <249 HB

3. Hardness after hardening: 52 HRC

4. Hardness after hardening and tempering at temperature:

Characteristic:

Tool steel has high thermal shock resistance and fatigue, good thermal conductivity, thermal tensile strength, tempering resistance, fine grain size and high toughness, additional fine structure without grain boundaries, cemented carbide, high creep strength Insensitive to high temperature and constant temperature changes, low P wave and S content, suitable for water cooling.

This level can be required by the production process, using EFS encryption, ESR or variable data.

Application :

High-pressure work tools, hot die forging presses use steel, copper, non-ferrous metals, and pressure casting dies.

Heavy and light metal alloys, mandrels, internal gaskets, stems, mold holders, extrusion gaskets, pressure pads, pillows, molds.

Metal container tube and rod extrusion, hot extrusion tools, monolithic insertion and die pressing, tools.

Manufacturing screws, nuts, bolts, rivets, hot shear blades, forging dies and stamping die blades, die castings.

Solar Special Steel International Limited

Contact Person :Wendy

Telephone:+86 18688633122 whatsapp&wechat

Skype: .cid.8920082fecfa0b5c

Email:ss@solarsteel.cn