Cr12MoV steel vs DC53 steel

From: Author:ss@solarsteel.cn Publish time:2021-10-09 16:50 Clicks:57

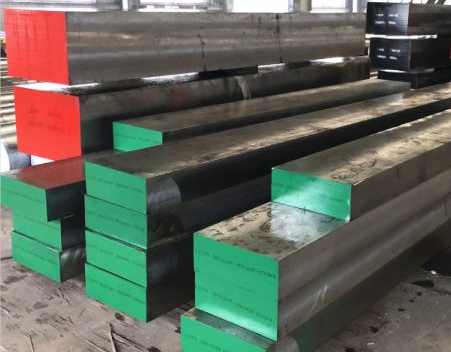

Cr12MoV steel and DC53 steel are belong to cold working die steels in mould steel’s marketing .

Cr12MoV steel and DC53 steel with good wear resistance and hardness between HRC58-62 after quenching process in the production .

DC53 steel ‘s hardness with 58-62 HRC which it is higher than DC53 steel’s quenching and tempering’s hardness . That’s the advantage of the DC53 steel .

DC53steel has better performance than Cr12MoV steel in many aspects, mainly in the following four aspects and its comparison .

Cr12MoV steel vs DC53 steel ‘s chemical component :

The carbon content of Cr12MoV steel is 50% higher than DC53steel. Cr12MoV steel is more likely to form carbide accumulation, resulting in poor local impact toughness.The impact toughness of DC53 steel is 2-4 times that of the steelCr12MoV.

It can be said that the die steel made of steel DC53 steel has better anti-cracking performance in application always .

DC53steel contains 2% Mo and 2Mo can be regarded as 1 W. Therefore, DC53 steel has better wear resistance than Cr12MoV steel.The wear resistance of DC53steel is about 3-6 times that of Cr12MoV steel.

Cr12MoV steel vs DC53 steel ‘s Temperature Issue :

The Mo content of steel DC53 high temperature resistant alloy is higher, about 4 times that of Cr12MoV.Therefore, steel DC53 can maintain high hardness for a long time in the case of high-speed stamping, and performs better than Cr12MoV steel.When stamping at high speed, DC53 mold steel wear resistance is 2-4 times better than Cr12MoV steel.

Cr12MoV steel vs DC53 steel ‘s Disparity in Cost :

The price of DC53 steel is about 2-3 times that of Cr12MoV steel.

In some of the industrial , there have some trading broker will take the steel of D2 to instead of DC53 , taking the Cr12MoV to replace the items of 1.2379 steel .

It is very common to say and view in China steel marketing in compete the price.

Please kindly to take the cautious to do the selection in material .

Solar Special Steel International Limited

Contact Person :Wendy

Telephone:+86 18688633122 whatsapp&wechat

Skype: .cid.8920082fecfa0b5c

Email:ss@solarsteel.cn