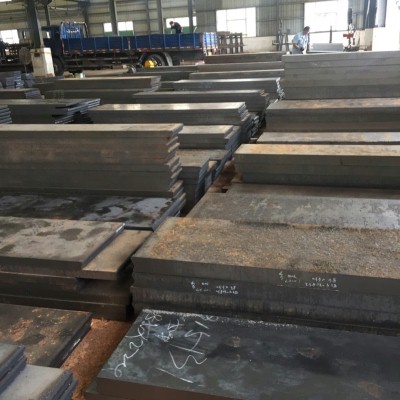

Detailed Introduction

Model :M50

Application : high speed steel

Content : Equivalent Steel with exact or nearest equivalents

|

Grade |

C |

Mn |

P |

S |

Si |

Cr |

V |

Mo |

|

M50 |

0.78-0.88 |

0.15-0.45 |

≤0.03 |

≤0.03 |

0.20-0.60 |

3.75-4.50 |

0.80-1.25 |

3.90-4.75 |

M50 is an American grade, which is the world's top steel for the main bearing of aero engines. The corresponding domestic steel grade is S8Cr4Mo4V.

International Standards

|

ITA |

USA |

GERMANY |

FRANCE |

UK |

CHINA |

|

X80MoCrV4 4 |

M50 / T11350 |

1.3551 |

Y80DCV42 16 |

BM50 |

Cr4Mo4V |

Physical properties of HSS UNS T111350 | M50 Tool Steel

· Density: 8.9kg/m3

· Thermal conductivity:

· Forging ratio: 5:1 Minimum

Mechanical properties of Alloy Steel UNS T111350 | M50 High Speed Tool Steel

Hardness: Annealing: 248 HB max, Q+T: 61 HRc Min, different hardness according different Tempering temperature.

Heat treatment of AISI M50 tool steel

· Annealing: Annealing temperature/℃: 750~790; After the annealing, degree of hardness ≤HBS: 255

· Quenching: Hardening temperature/℃: 1104, Quenching in Salt bath furnace

· Tempering: Commonly used drawing temperature/℃:5382; After tempering hardness HRC : 61 HRc Min

· Normalizing:at Normalizing temperature, then cool in furnace

Forged steel properties of M50 high tool steel

For forging UNS T111350 | M50 steel, Slowly Pre-heat, at temperature/℃: 900~1100 Forged

|

Heat-Treating Requirements

|

|||||

|

The austenitizing temperatures are stipulated for the response to hardening test only. Other combinations of austenitizing and tempering ,temperatures may be used for particular applications |

|||||

|

Class

|

Preheat Temperature °F (°C)

|

Austenitizing Temperature, °F (°C)A

|

Tempering Temperature, °F (°C)B

Salt Bath

|

Tempering Temperature, °F (°C)B Controlled Atmosphere Furnace |

Minimum Hardness, Rockwell C

|

|

M1 |

1350–1550 (732–843)

|

2185 (1196)

|

2205 (1207)

|

1025 (552)

|

64

|

|

Macroetch Standards Maximum Allowable RatingA

|

||||

|

Bar Size, in. (mm) |

T Classifification SteelsB |

M Classifification SteelsC |

||

|

|

Porosity |

Ingot Pattern

|

Porosity |

Ingot Pattern |

|

UP TO2(50.8)incl |

3 1⁄2 |

5 |

3 |

5 |

|

Over 2 to 3 (50.8 to 76),incl |

4 |

5 |

3 1/2 |

5 |

|

Over 3to 4 (76to 102),incl |

4 1/2 |

5 |

4 |

5 |

|

Over 4 to 5(102 to 127),incl |

5 |

5 |

4

|

5 |

|

Over 5 to 6(127 to 152),incl |

5 |

5 |

4 1/2 |

5 |

|

Over 6 (152) |

As negotiated between supplier and purchaser |

|||

Solar Special Steel International Limited

Contact Person :Wendy

Telephone:+86 18688633122 whatsapp&wechat

Skype: .cid.8920082fecfa0b5c

Email:ss@solarsteel.cn